Product Overview

This unique and patent-protected concept commenced development by the team at CombiTile® in 2016 in recognition of a need in the playground surfacing market.

The surfacing product used for attenuation in play areas must comply with standards such as AS4422:2016 in Australia, ASTMF1292 in the USA and EN1176-2008 in Europe.

These standards reflect the safe fall height required by various surfacing products including artificial grass, troweled SBR, rubber matting and loose fill.

The CombiFlex and CombiLock products have all achieved certification under these critical fall height standards. CombiLock has also achieved certification under ASNZ4586– Appendix C Wet-Barefoot Inclining Platform Test.

The CombiTile products are critical fall height tested and certified, recyclable, durable, UV stabilsied, chlorine resistant, contain no VOCs, are lightweight and durable with a 5 year product warranty and are insured for public liability and product integrity.

They are repositionable, lightweight, can be installed in all but the worst of weather conditions. They require no harmful adhesives and solvents that are a danger to the health of the play area users and installers. And they pose no threat to the environment.

How CombiFlex is used in various applications

The Problem

Existing Playground Surface Issues

- Can have inconsistent density due to varying pressure applied during installation

- Carbon leaching from used car tyres

- Relies on the skill of the installer

- To achieve the same critical fall height

- Can compress over time affecting fall height rating;

- Bulky and expensive to transport

- Labour intensive to install;

- Porous nature leaves open the possibility of harboring health related threats;

- Can degrade in a water park environment;

- Difficult to drain

- Expensive, bulky and heavy to transport

- Must be glued with associated VOCs

- To achieve 3m (9.8 feet) fall height 100mm (3.9 inches) of cushion is required

- Health related issues due to porous nature and ability to harbor potential threats;

- Can degrade in a water park environment;

- Difficult to drain

- Must be raked and cleaned regularly;

- Can consolidate over time leading to non-compliance;

- Not disable access friendly;

- Costly when maintenance and top-up requirements are considered;

- Can conceal small objects such as needles;

- Attracts animals causing associated feces and hygiene problems;

- Small chips can be potential danger to young children;

- Can cause maintenance problems when thrown by children onto surrounding grass;

- Efficient drainage difficult to achieve.

- Fill consolidation and agglomeration;

- Increased surface temperature;

- Toxicity associated with some types of fill;

- Inconsistent shock attenuation;

- High maintenance cost

Our Solution

The CombiTile® System

- Critical fall height of 2.7m tested under synthetic grass ASNZ4422

- Easy Installation

- Ideal for both dry and wet playgrounds

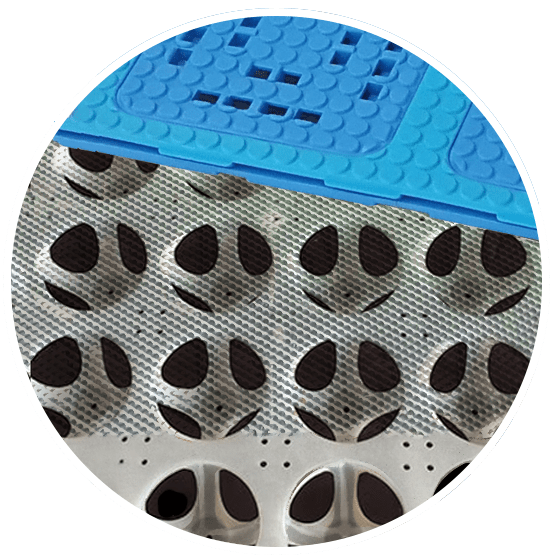

- Attenuation & drainage in one

- Cost effective, cheaper than most attenuating systems

- Long lasting & simple to repair if required

- Ideal for both dry and wet playgrounds

- Lightweight, stackable, inexpensive to transport

- Will reduce sport-related injuries

- The CombiFlex system allows pre-determined shock attenuating properties

- In artificial grass applications – good drainage, cleaner surface and increased longevity

- Under loose fill applications is easier to maintain, keep clean and offers permanent attenuating properties

The CombiTile® System

- Critical fall height of 2.7m tested under synthetic grass ASNZ4422

- Easy Installation

- Attenuation & drainage in one

- Cost effective, cheaper than most attenuating systems

- Long lasting

- Simple to repair if required

- Ideal for both dry and wet playgrounds

- Lightweight, stackable, inexpensive to transport

- In artificial grass applications – good drainage, cleaner surface and increased longevity

- The CombiFlex system allows pre-determined shock attenuating properties

- Will reduce sport-related injuries

- Under loose fill applications is easier to maintain, keep clean and offers permanent attenuating properties

CombiFlex Installation Guide

CombiLock/ CombiFlex Drop Test

SYNTHETIC GRASS

INTERLOCKING TILE

UNDER LOOSE FILL

Water Park Surfaces

CombiLock®

While the great majority of water parks are outdoors, recent years have seen more indoor venues built for year-round use, particularly in colder climates.Water parks require sustainable and economical surfaces with drainage – add the requirement of safety, anti-slip and reduced chemical usage the CombiTile productsare your solution.

Requirements

CombiLock meets the following criteria

- Slip resistant under ASNZ4586:2013;

- Certified critical fall height;Cost effective life cycle;

- Attractive and appealing to children;

- Minimum 5 year life span;

- Minimal fade and appearance retention;

- Chlorine resistant;

- Mould and fungus resistant;

- Saves water

Performance

CombiLock’s performance benefits

- Slip resistant surface under ASNZ4586:2013;

- Reduces water evaporation

- Handles continual wear and tear in a play environment;

- Easily repaired with minimal visual impact;

- Recyclable and relocatable;

- Mould and fungus resistant;

- Impact attenuation where required by Australian Standard

Aesthetics

New - Colour Selector Tool

CombiLock tiles are available in eight standard colours , however can now be matched to most Pantone colours based on minimum orders of 2500 units. Use our new COLOUR SELECTION TOOL to experiment with different colour combinations (loads in a new window).

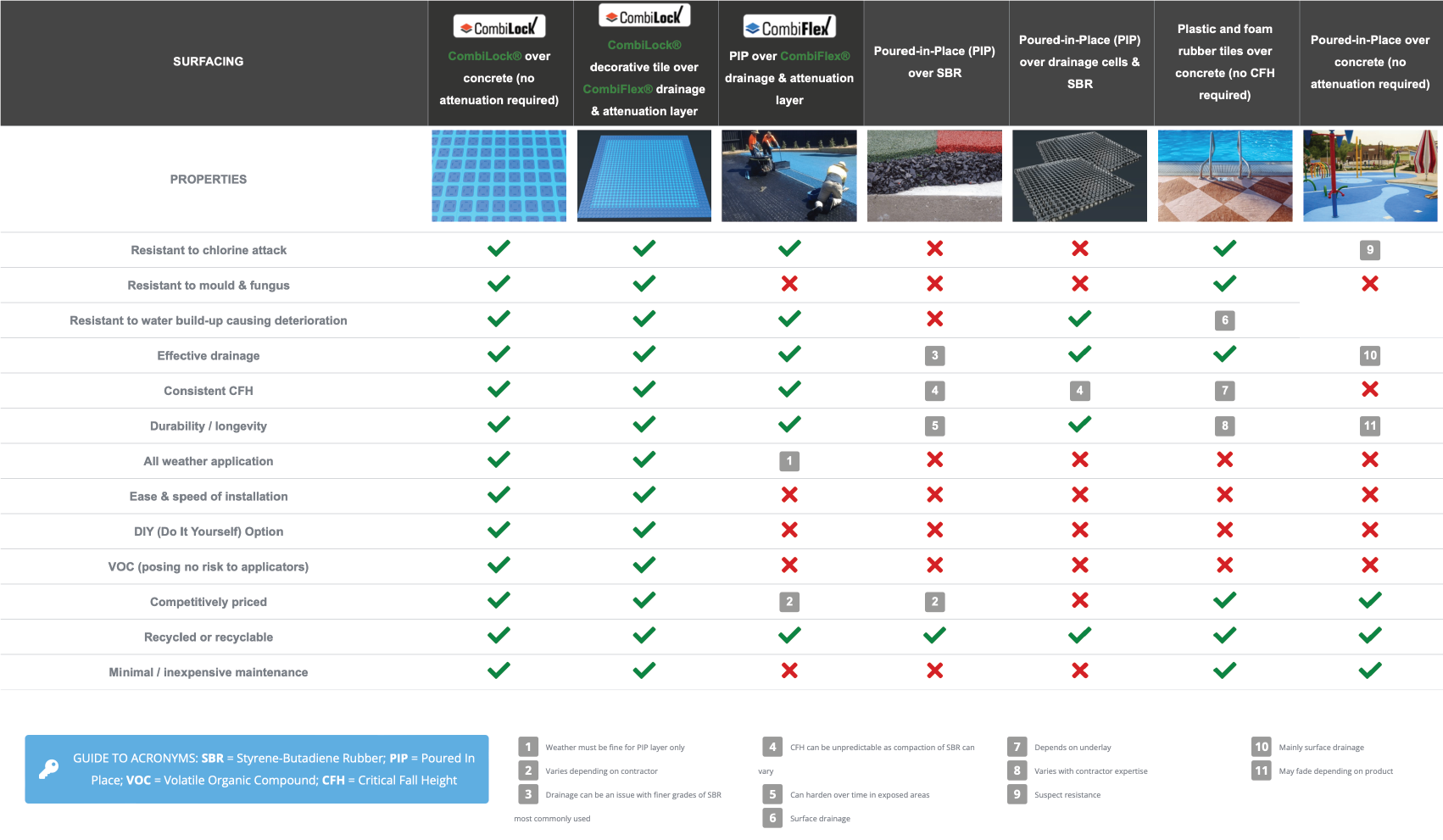

Comparisons

Transport & Installation of surface systems

- Heavy and expensive to transport

- Must be stored in dry conditions and temperature must be compatible with adhesives

- Requires skilled labour, is messy and is physically demanding

- Use adhesives such as polyurethane and require the use of face masks to comply with safety regulations

- Weather plays a major part with installations resulting in expensive delays

- Easily stored on-site in any conditions

- CombiTile Systems are light (over 700m2/20′ container) and easily handled leading to cheaper transport.

- CombiTile Systems are simple and easy to install and require little skill.

- CombiTile Systems do not require adhesives.

- CombiTile can be installed in all but the worst weather conditions.